FULLY AUTOMATIC SCREENCHANGER, up to 3 Tons/h

FULLY AUTOMATIC SCREENCHANGER, up to 3 Tons/h

Contact us for price

Description

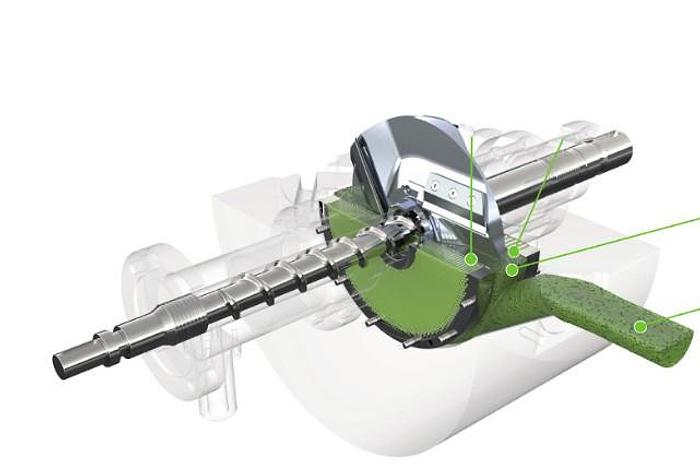

The most cost effective solution for extruders up to 3.000 kg/h.

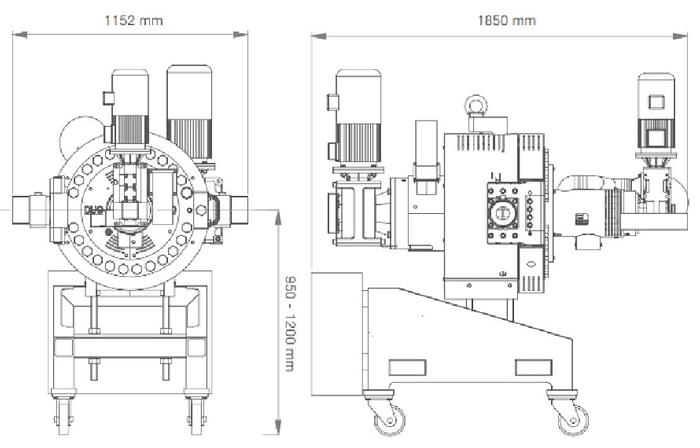

Very compact shape, less metal to heat up.

High resistance to pressures line (up to 350 bar).

Minimum material waste due to the continuous cotamination removal.

Adjustable speed of the discharge screw allows the finest handling. Continuous cleaning allows to use filters longer than traditional technologies.

Pressure is kept constant all the time for a more even process

Easy maintenance: filter replacement easier and faster, without removing machine’s components. Also available with an automatic opening system that makes opening and closing lid’s operations easier, faster and safer.

Double screening system : 2 x Ø 370 mm.

With laser screens (from 60 to 350 µm)

punched screens (from 400 to 2000 µm),

metallic mesh screens (from 230 to 10 mesh).

Bespoke screens available since they are produced in-house.

Laser and punched screens withstand wear and high temperatures.They can be cleaned in a pyrolytic oven to be re-used several times.

This machine can switch from doctor-blade mode to back-flush mode simply by changing the kit of internal components. In this mode, only mesh filters will be used. This mode is suggested with light contamination.

Contact us with your project's details:

- Kind of material

- MFI

- Throughput rate in kg/h

- % and kind of contaminants

- Mesh size

to get your quotation now.

This machine is replacing the most conventional ones for its compactness and affordabily.

Specifications

| Manufacturer | ITALIAN |

| Model | 3 Tons/h FULLY AUTOMATIC SCREENCHANGER, doctor-blade type |

| Condition | New |

| Stock Number | SGB800 |

| function | screening - fully automatic |