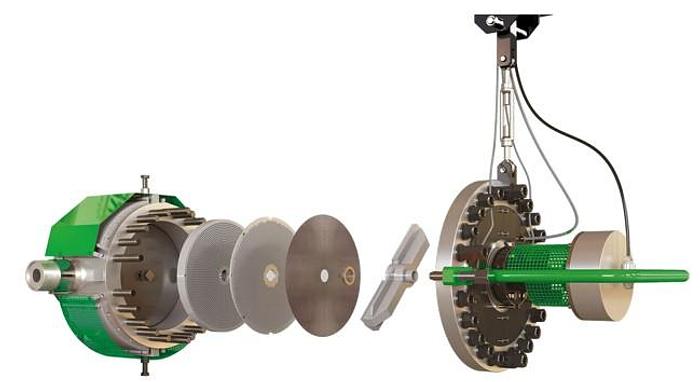

SGB400 AUTOMATIC SCREENCHANGER 400 mm.

SGB400 AUTOMATIC SCREENCHANGER 400 mm.

Contact us for price

Description

FULLY AUTOMATIC DOCTOR BLADE SCREENING SYSTEM

Materials filtered : PP-LDPE-LLDPE-HDPE-PS-EPS-XPS-ABS-TPU

Components and technical features

- Filter diameter 400 mm - filtering surface 1.206 sqcm

- Machine central body derived from a single piece

- Electric motor and gearbox

- Nr. 2 scraping impellers for scraping operation complete with blades

- Nr. 2 Breakers for scraping operation (45mm + 8mm)

- Nr 1 discharge slide (under the valve)

- laser screens from 60 to 300 my (mesh from 230 to 50

- Punched screen from 400 to 2.000 my (mesh from 40 to 10)

Electrical panel adaptable to UL/CSA standards

- 1 inverter for motor management

- 1 filter for inverter

- 3 thermoregulators and static relays for resistance management

- 3 thermocouples

- 2 interceptors with Melt probe for alarm and cleaning management

- Fuse protection for the various power supplies

- Machine status reporting provisions

- Switch-disconnector with door lock function

- Track to facilitate lid opening and closing

- programming and wiring diagrams

- motor power supply cables

- user power cables

- sensor cables

STARTER KIT with spare parts Nr.2 punched filters for 400 microns

10 pcs scraper blades 2 pcs nut

1 pcs tall nut 2 pcs stud bolt

2 pcs long stud bolt

2 pcs cleaning spatula

2 pcs silicon spray for cleaning operations 1 pcs pneumatic cylinder seal

1 pcs valve release equipment

1 pcs spacer for scraper impeller

1 internal ring for scraping impeller

1 pcs impact socket drives 3/4 exag. 46mm l63

2pcs coupling safety Screw M12x100 UNI 5737 DIN 931 – 8.8

OPTIONAL - to be quoted separately

- kit for backflushing operations

- Electrical cabinet 4.0 system with PLC

- Connection flanges and heaters

Specifications

| Manufacturer | ITALIAN |

| Model | AUTOMATIC SCREENCHANGER 400 mm. |

| Year | 2024 |

| Condition | New |

| Stock Number | SGB400 |

| Screening Surface | 400 mm. Ø - 1.206 sqcm |